How CanadaŌĆÖs oilsands can help build better roads

July 22, 2022

Share

The future seems bleak for CanadaŌĆÖs oilsands. But given the worldŌĆÖs ongoing need for smooth, safe roads, there is hope for the industry. Asphalt binder made from oilsands bitumen is the ideal glue to hold together ŌĆö and it can be done sustainably, economically and environmentally.

With the underway, and to meet its Paris Agreement obligations, Canada will use less fossil fuels, especially from imports and upgraded products, including those from the Alberta oilsands.

With the underway, and to meet its Paris Agreement obligations, Canada will use less fossil fuels, especially from imports and upgraded products, including those from the Alberta oilsands.

│╔╚╦┤¾Ų¼ 10 per cent of CanadaŌĆÖs current emissions come from the extraction and upgrading of crude bitumen from the oilsands, . Globally, about are from burning fuels for electricity, heat and transportation, and from industry.

Our research group has investigated the life-cycle performance of asphalt roads for the past 30 years, providing some remarkable insights on the , produced with minimal refining and without upgrading. Producing asphalt binder from Alberta crude bitumen can realistically .

Low-quality asphalt leads to more repairs

Alberta bitumen is low in wax, making it highly desirable for the production of asphalt binders. The ŌĆö supporting a true circular economy.

due to heavy traffic, and the incorrect use of reclaimed materials to rehabilitate and reconstruct old roads. The use of so-called green technologies ŌĆö inexpensive, recycled engine oil, for example ŌĆö .

Government transportation agencies arenŌĆÖt incentivized to use stronger binders. Yet pavement cracking can be reduced by building roads that maximize the use of straight, unadulterated Alberta binder.

Doing so allows municipal, provincial and state infrastructure owners around the world to reduce construction and rehabilitation budgets, and .

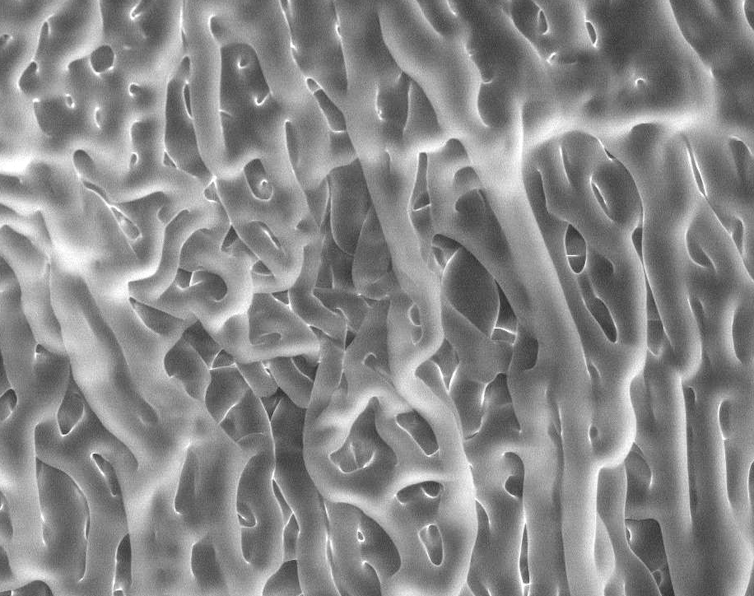

Binders are complex materials

Two binder components influence the lifespan of roads: asphaltenes and waxes. Asphaltenes are (the adhesiveŌĆÖs ability to hold itself together) and adhesive strength (the strength between the adhesive and another material), but prevent it from flowing at cold temperatures. , occurring in varying amounts depending on the source of the crude used to manufacture the binder.

The binder is a mixture of solid asphaltenes and waxes in an oily material. When the wax content is high, . A high-wax binder is stiffer at cold temperatures, which reduces adhesion and promotes cracking. An optimal binder has minimal wax and has a more-or-less uniform composition.

Poor-quality binder is costly

Construction specifications for asphalt often fail to identify poor performing binders. More than a few substandard binders are . Oilsands crudes have the lowest wax contents of all sources and can produce top-quality binders.

Alberta binders of various grades perform well on their own, without additives, as long as they are used with good pavement designs. However, .

For example, a 12-year-old test section of asphalt in northern Ontario, constructed with top-quality binder from Alberta, and modified with 0.3 per cent of recycled PET fibre shows virtually no distress today. ; a significant improvement compared to historical 15- to 25-year performance cycles.

Producing asphalt binder from Alberta oilsands will not only reduce the industryŌĆÖs greenhouse gas emissions by 40 to 60 per cent, but can also extend pavement lifespan by 30 to 50 per cent.

Fuel and asphalt demands are headed in opposite directions

Today, , and . As government regulations shift to lower greenhouse gas emissions, companies that extract and/or produce crude oil will see lowered demand, and be pushed to create products that donŌĆÖt need to be refined or wonŌĆÖt be burned. , making bitumen a strong contender for use as an asphalt binder.

. Asphalt-paved roads are safer than unpaved roads, and are more economical for a greater volume of traffic.

The volume of unpaved roads globally presents a tremendous economic opportunity. Carbon pricing and credits will hasten the bitumen transition. Producing high-performing asphalt binders from Alberta crude bitumens ŌĆö especially those extracted through that require a smaller surface area ŌĆö can position the oilsands industry to remain viable.

Alberta has enough bitumen to supply the global road-building industry for more than 100 years if oilsands companies divert about 50 per cent of each barrel to produce asphalt binder.

_______________________________________

Jen Kovinich, Aiden Kuhn and Alison Wong, undergraduate research assistants at QueenŌĆÖs University, co-authored this article.![]()

, Professor of Chemistry, and , Assistant Professor, School of Civil Engineering,

This article is republished from under a Creative Commons license. Read the .